Mit unserer industriellen Messtechnik können Sie die Qualität Ihrer Werkstücke über den gesamten Produktionsprozess hinweg effizient überwachen und sicherstellen.

HOMMEL ETAMIC entwickelt und baut industrielle Messtechnik, mit der Sie Ihre Fertigungsprozesse überwachen und optimieren können. Unsere taktilen, pneumatischen und optischen Messsysteme sind auf dem neuesten Stand der Technik und übernehmen je nach Anforderung unterschiedlichste Messaufgaben. Sie analysieren die Oberfläche, Form und Dimensionen Ihrer Werkstücke – und das in jeder Phase des Fertigungsprozesses, bei der Endkontrolle oder im Messraum. Dabei liefern Ihnen die Systeme präzise Messdaten innerhalb kürzester Zeit.

Als ein führender Hersteller und Systemlieferant bieten wir ein breites Leistungsspektrum an. Wählen Sie aus einer Vielzahl an Standardprodukten das System, das Ihren Anforderungen am besten entspricht. Bei Bedarf entwickeln wir Systeme, die exakt auf Ihre Bedürfnisse zugeschnitten sind. Dank unseres umfassenden Know-hows und unserer jahrzehntelangen Erfahrung kennen wir die Wünsche und Ansprüche unserer Kunden genau. Gemeinsam mit Ihnen finden wir das passende System – lassen Sie sich von unseren Experten beraten!

Unser Service steht Ihnen weltweit zur Verfügung, er wartet und repariert Ihre Systeme zuverlässig.

HOMMEL ETAMIC - Industrielle Messsysteme

Was wir Ihnen bieten

Präzise Prozesse

100 %-Kontrolle

Globale Präsenz

weltweit erreichbar

Qualitätssicherung

automatisierter Produktionsprozesse

Plug and Play

Systemintegration

HOMMEL ETAMIC Messsysteme

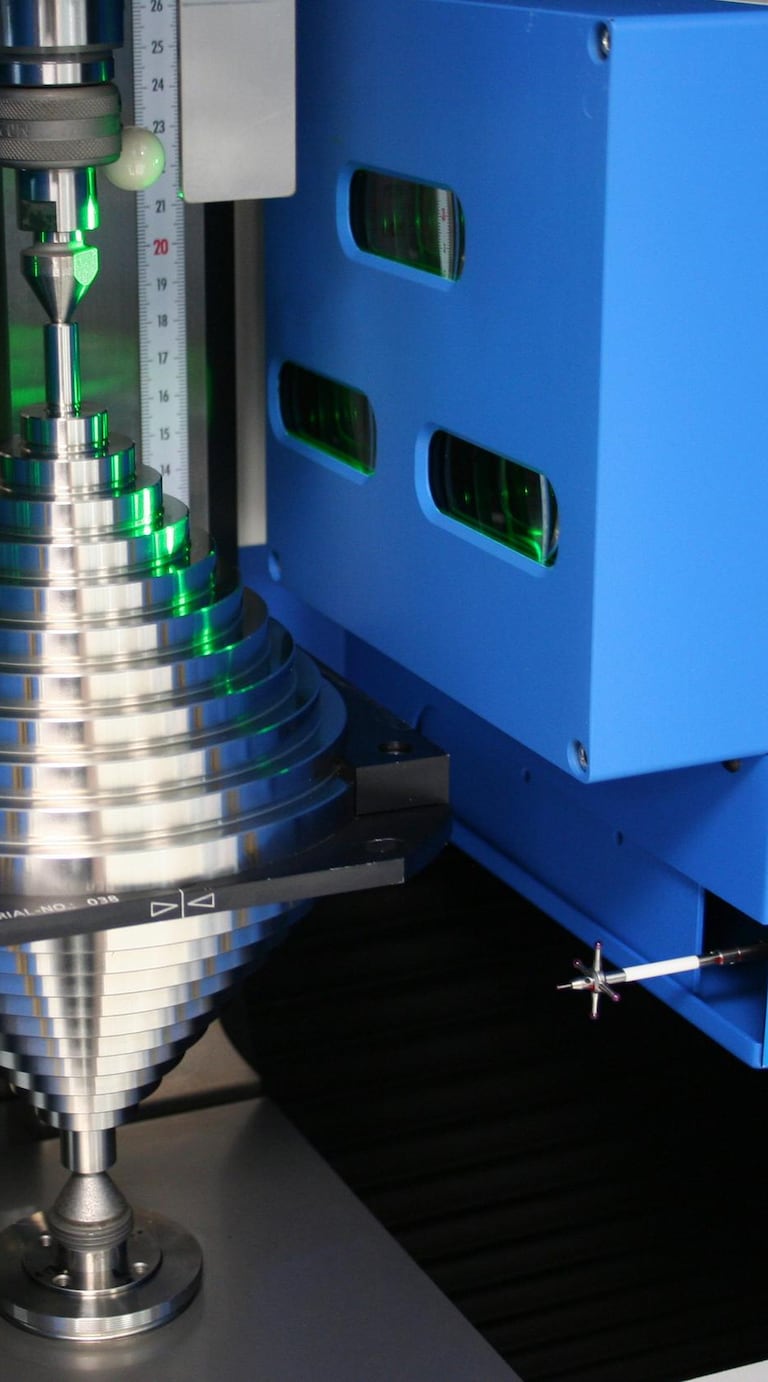

Formline | Formmesssysteme

Mit unseren Formmessgeräten können Sie problemlos rotationssymmetrische Werkstücke überprüfen. Durch einen weitestgehend automatisierten Messvorgang können verfälschte Ergebnisse vermieden werden.

Waveline | Rauheits- und Konturmesssysteme

Messen Sie die Rauheit und die Kontur Ihrer Werkstücke mit der Messtechnik von HOMMEL ETAMIC. Sie haben die Wahl zwischen mobilen und stationären Messgeräten. Ebenso können Sie zwischen getrennten Messabläufen oder einem einzigen Tastschritt wählen.

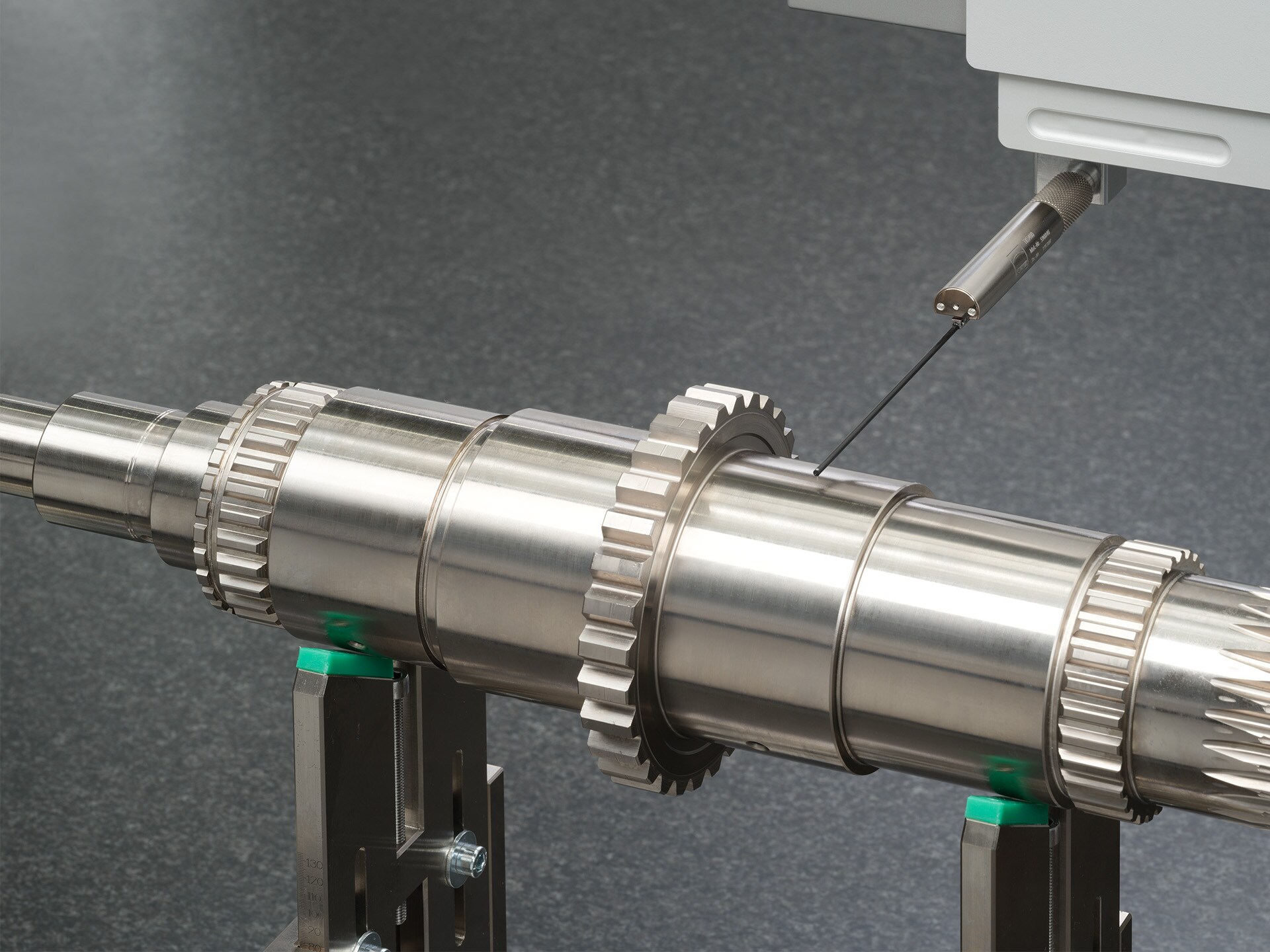

Opticline | Optische Wellenmesssysteme

Unsere Wellenmesssysteme liefern Ihnen dank des optisch-berührungslosen Messprinzips präzise Ergebnisse innerhalb weniger Sekunden.

HOMMEL ETAMIC Prüfsysteme

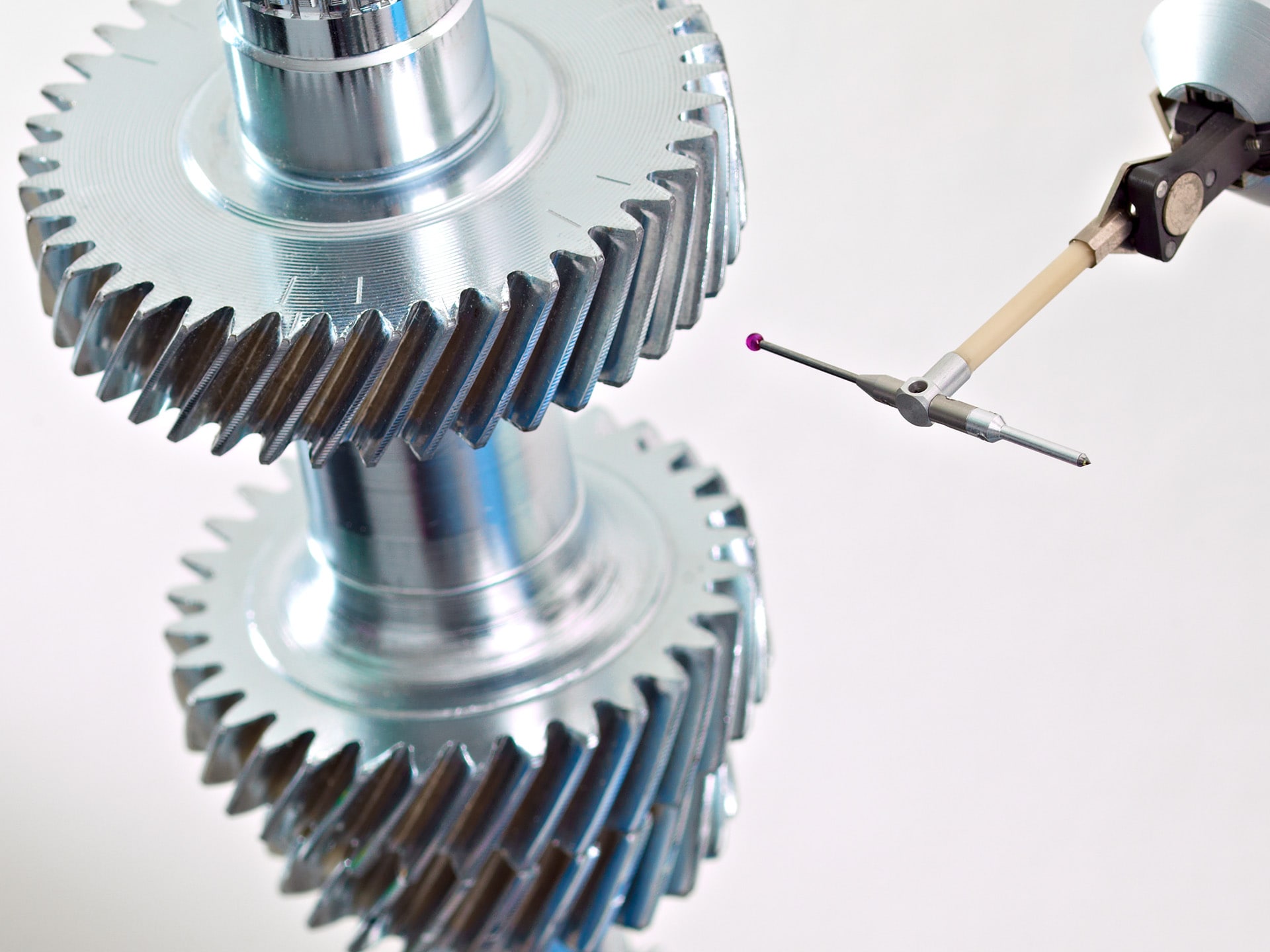

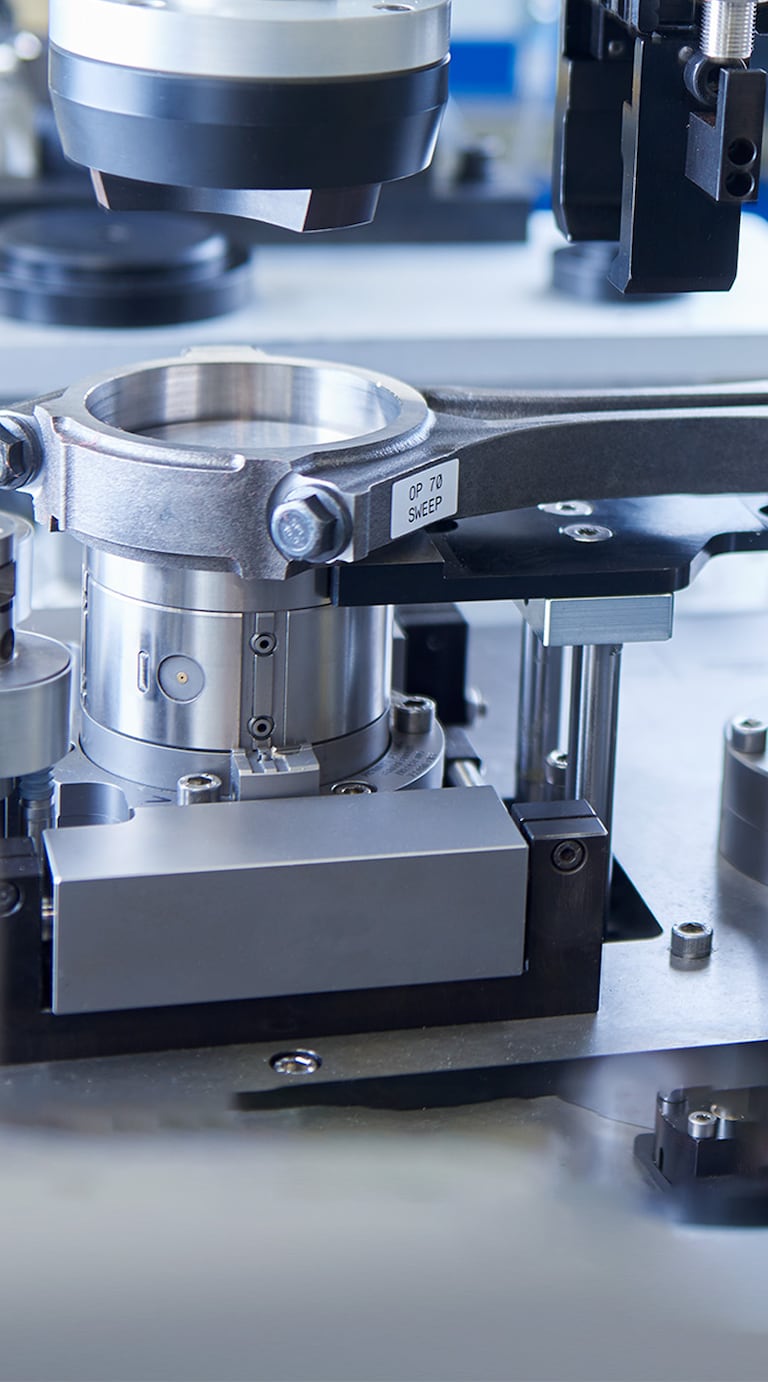

Gageline | Dimensionelle Prüftechnik

Nutzen Sie für Ihre Werkstücke die dimensionelle Messtechnik von HOMMEL ETAMIC und überprüfen Sie damit Durchmesser, Längen, Abstände, Form und Lage. Je nach Messaufgabe können Sie sich für eine pneumatische oder taktile Messmethode entscheiden.

Visionline | Optische Oberflächeninspektion

Erkennen Sie mit der optischen Oberflächeninspektion von HOMMEL ETAMIC minimale Fehlerstellen und verbessern Sie dadurch die Qualität Ihrer Werkstücke. Hochauflösende Kamerasysteme und hohe Prüfraten erkennen Fehlerstellen sofort und taktzeitgerecht.

Lassen Sie sich von unseren Experten beraten!