Modular Beam Splitting System MBSS for efficient solar cell production

High-precision meets high-performance

Stay flexible to keep your processes cost-effective

While you focus on your core expertise, we handle the optical setup and testing. Receive a fully assembled, ready-to-install laser system weighing under 10 kg. Simply select your desired parameters (wavelength, spot size, and spot distance) and we will take care of the entire optical configuration. Plus, enjoy the flexibility to adjust features and hardware setup anytime.

Reliable laser scribing process for Perovskite Solar Cells (PSC)

Enabling minimized dead zones and higher power efficiency

FAQ about the Jenoptik MBSS

What is a typical application for the MBSS?

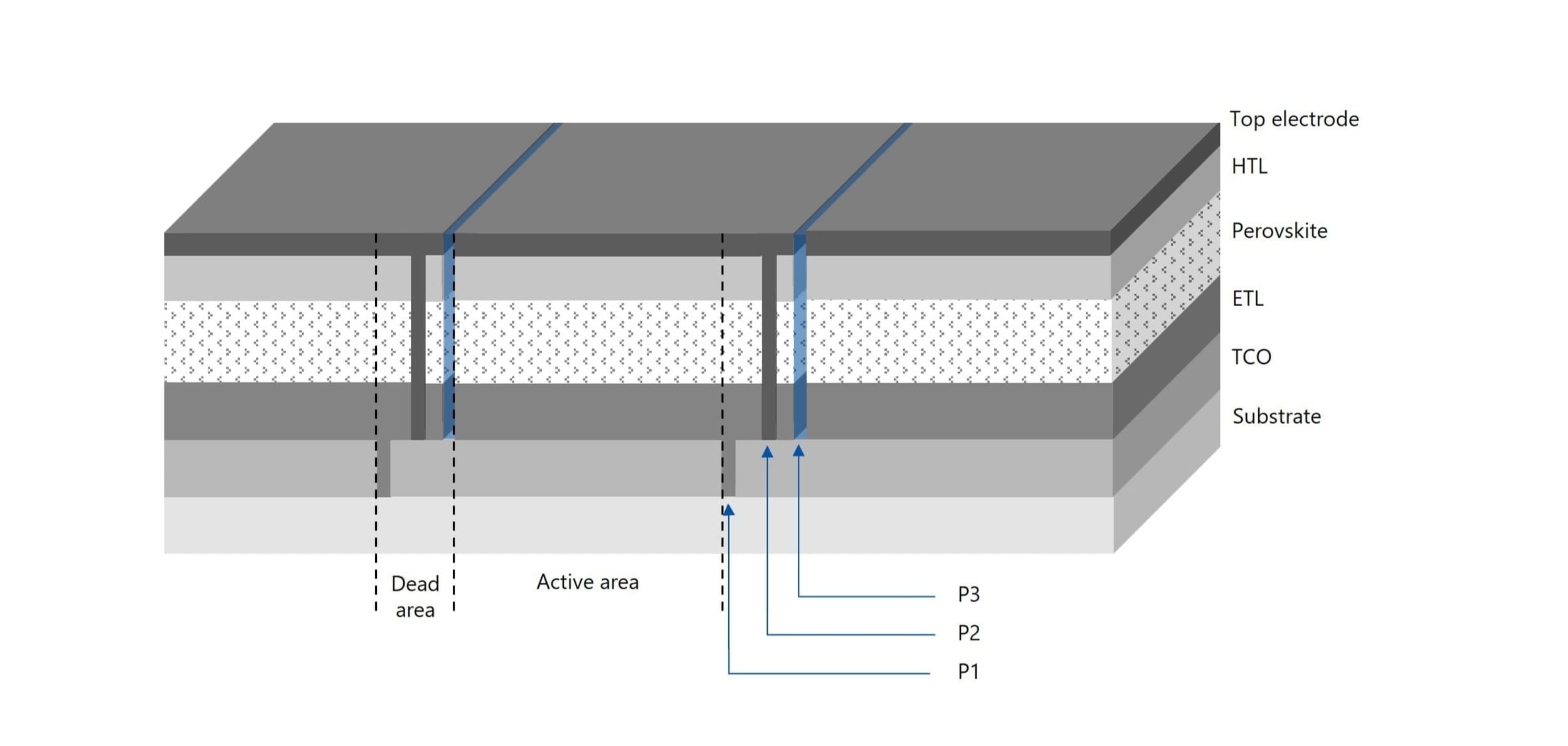

Three steps of the Laser scribing process:

- P1 for bottom electrode scribing

- P2 for semiconductor components scribing

- P3 for top electrode scribing

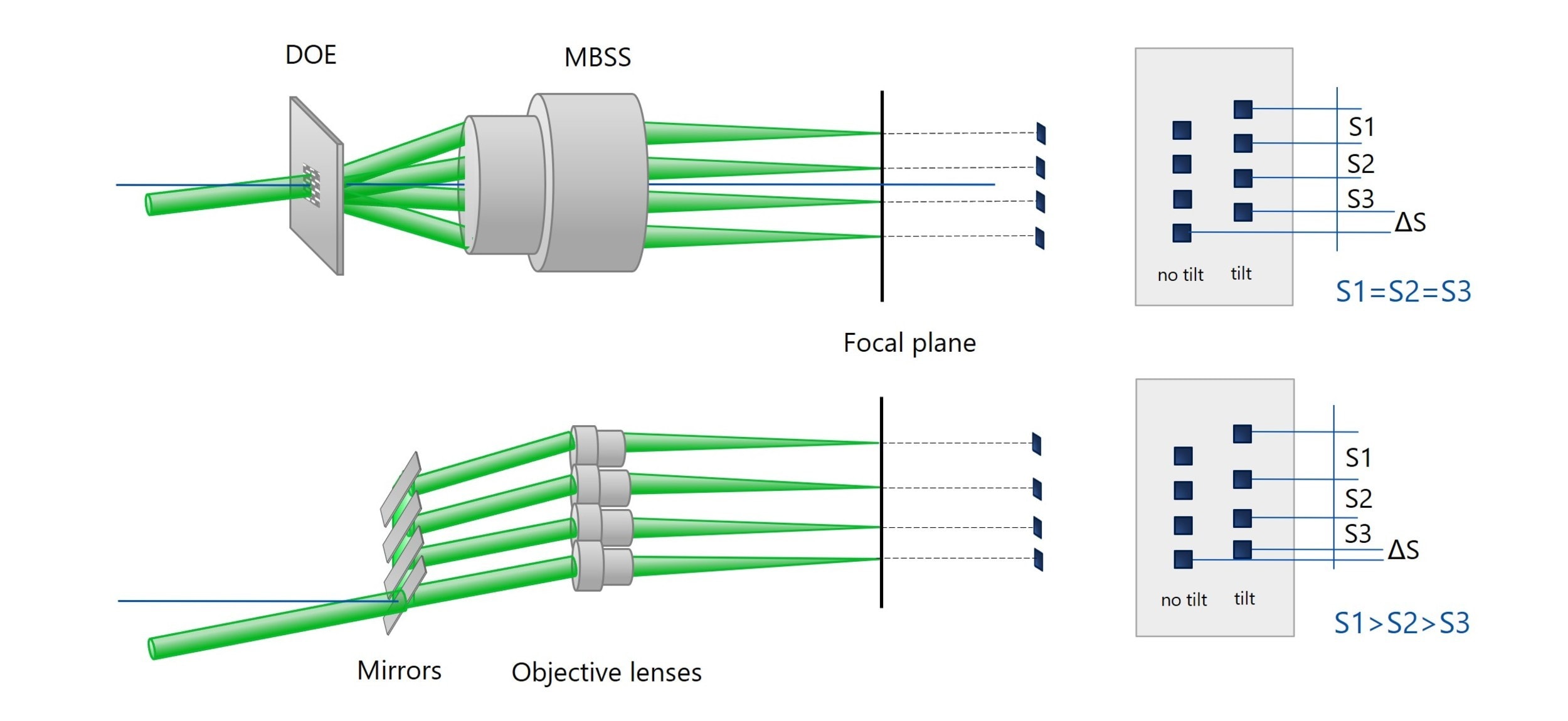

What is the benefit of MBSS if there is variation of input laser beam point direction?

For the approach with a classical beam splitter, Input laser beam tilt may cause the shift of beam incident location on each mirror, which result in variation of the pitch uniformity for output beams. See image below.

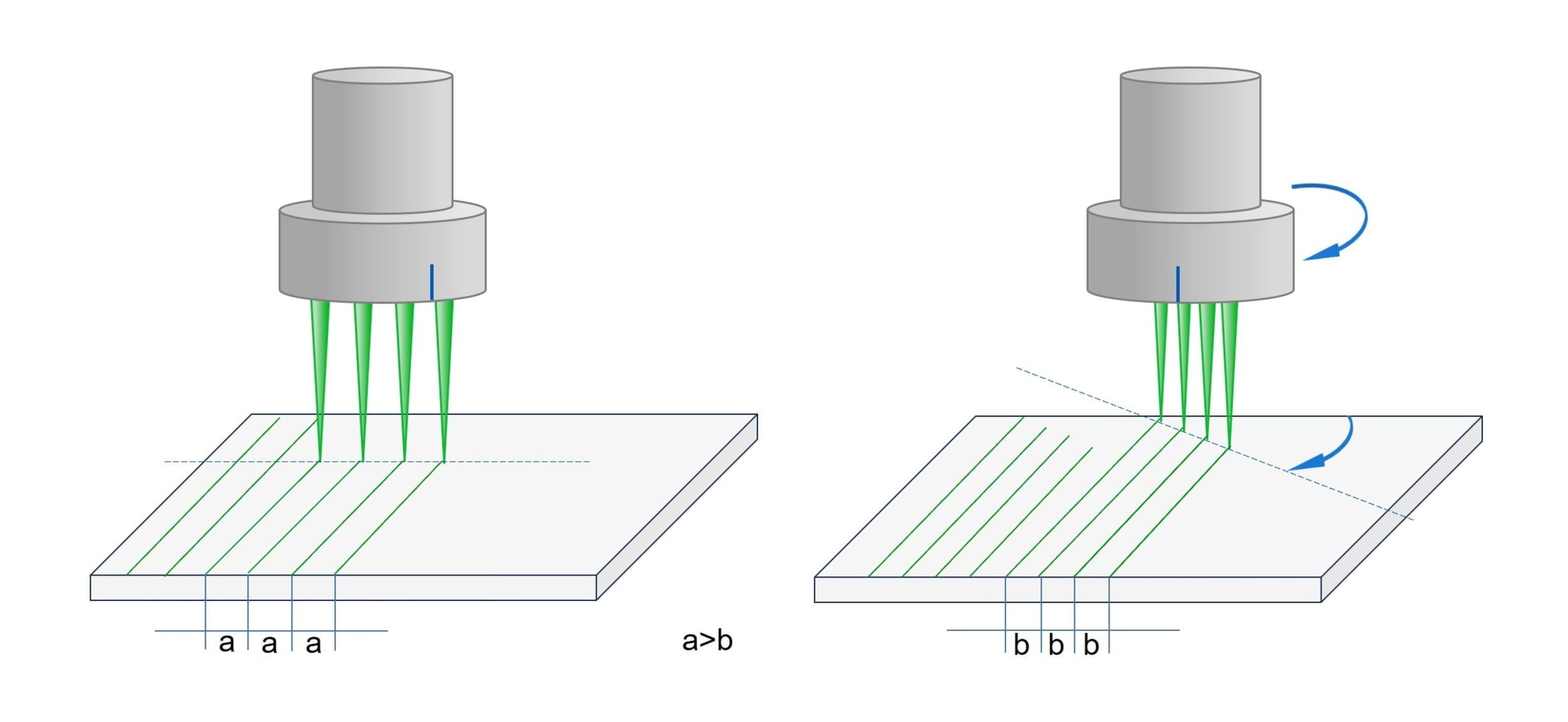

Whether customized MBSS possible, and how can the width and pitch of laser scribing line be adjusted?

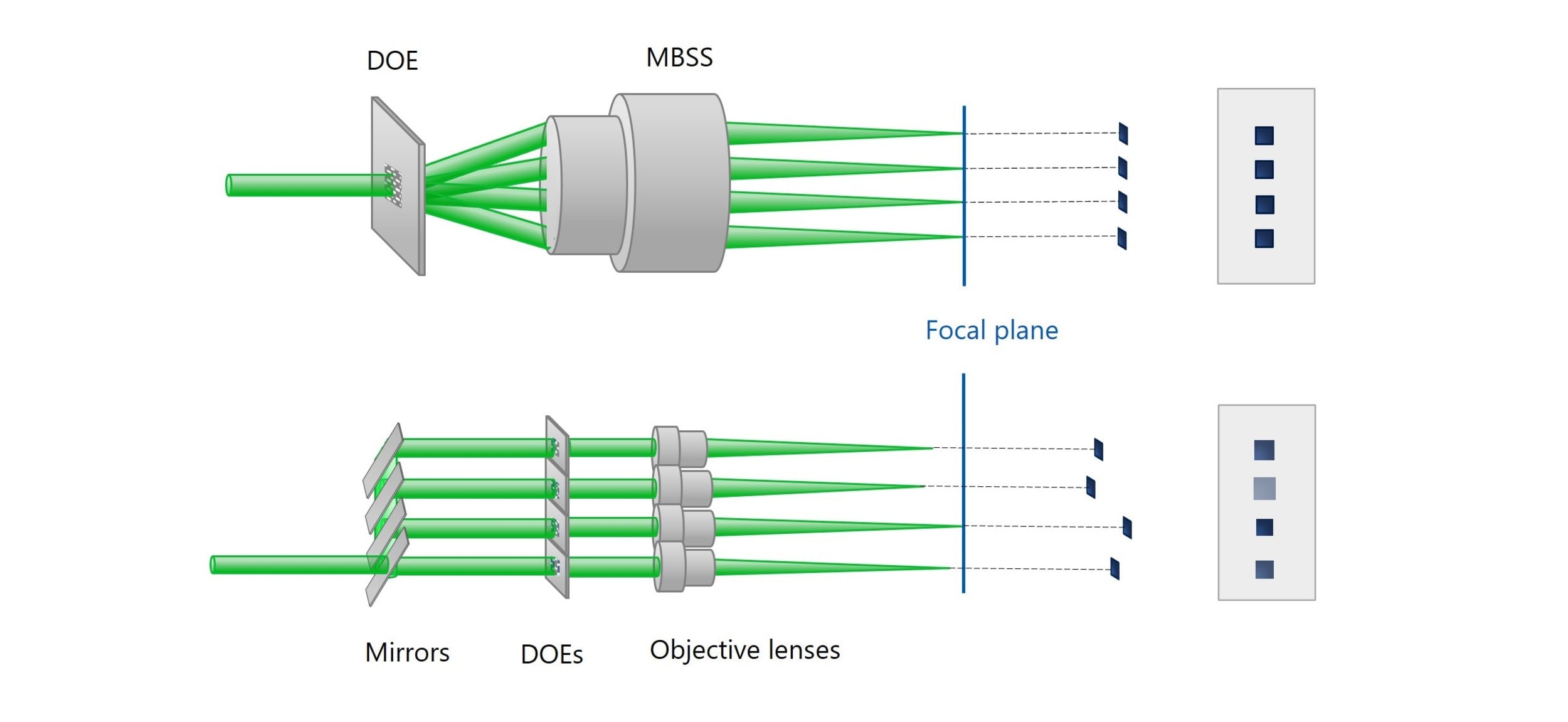

Why MBSS has the advantage of integrating DOE beam shaper for top-hat laser scribing?

A top hat beam shaper, for example, can be used to create certain shapes, like circles, squares, rectangles, lines, or others. As a diffractive optical element (DOE) the Beam shaper convert a near-Gaussian laser beam into a uniform-intensity spot with sharp edges. The result is a beam with a consistent intensity distribution across its entire surface, which is perfect for applications that require precise control over the beam's shape and intensity.

MBSS approach generates top-hat array by integrating single DOE beam shaper element. The beam shaper alignment takes only one time so much less efforts than traditional beam splitter system. In addition, MBSS multiple beams are emitted through a single optical system, therefore optimized top-hat array locate at the same focal plane, have equal top hat size with the same intensity distribution With MBSS, multiple beams are emitted through a single optical system. This makes it possible to utilize the entire depth of focus range of the lens.

Disadvantages of a classical beam shaping array with mirrors and DOEs:

- Individual DOE beam shaper for each channel need a lots of efforts for top-hat calibration.

- Objectives focal length variation results in the deviation of top hat size, top hat intensity, and the intensity distribution in top hat.

- The deviation of individual focal length may cause unequal top-hat size. Individual beamlet de-focus status result in uneven ablation effect on workpieces.

MBSS approach with one DOE for homogenous beamlets. Classical approach using beam shaping array with mirrors and DOEs.

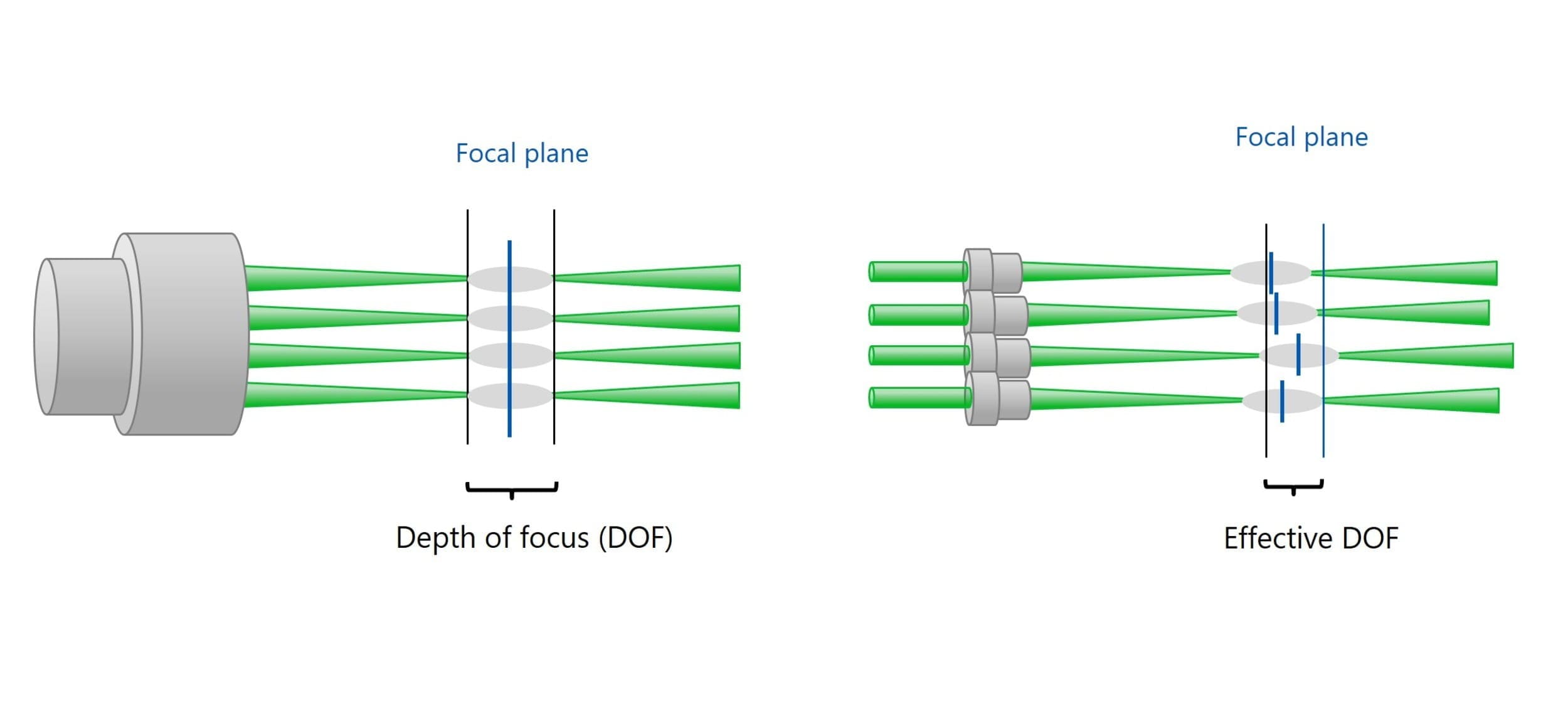

Why MBSS can perform exceptional depth of focus (DOF) compared to traditional solutions?

With Jenoptik's Modular Beam Splitting System, multiple beams are emitted through a single optical system. This makes it possible to utilise the entire DOF range of the lens.

The MBSS solution provides a value of DOF >+/-1.0mm. This means that there is no need to integrate a focus tracking system into the laser system. In addition, the larger depth of focus (compared to existing optical setups) allows Jenoptik's MBSS to be used for both rigid and flexible perovskite solar cell laser scribing processes.

On the left: MBSS Approach with single focal plane and no significant shift On the right: For classical beam splitter system, each beamlet output comes from individual optical path. The deviation of focal length may cause the shift of focal planes result in a smaller DOF overlap area.

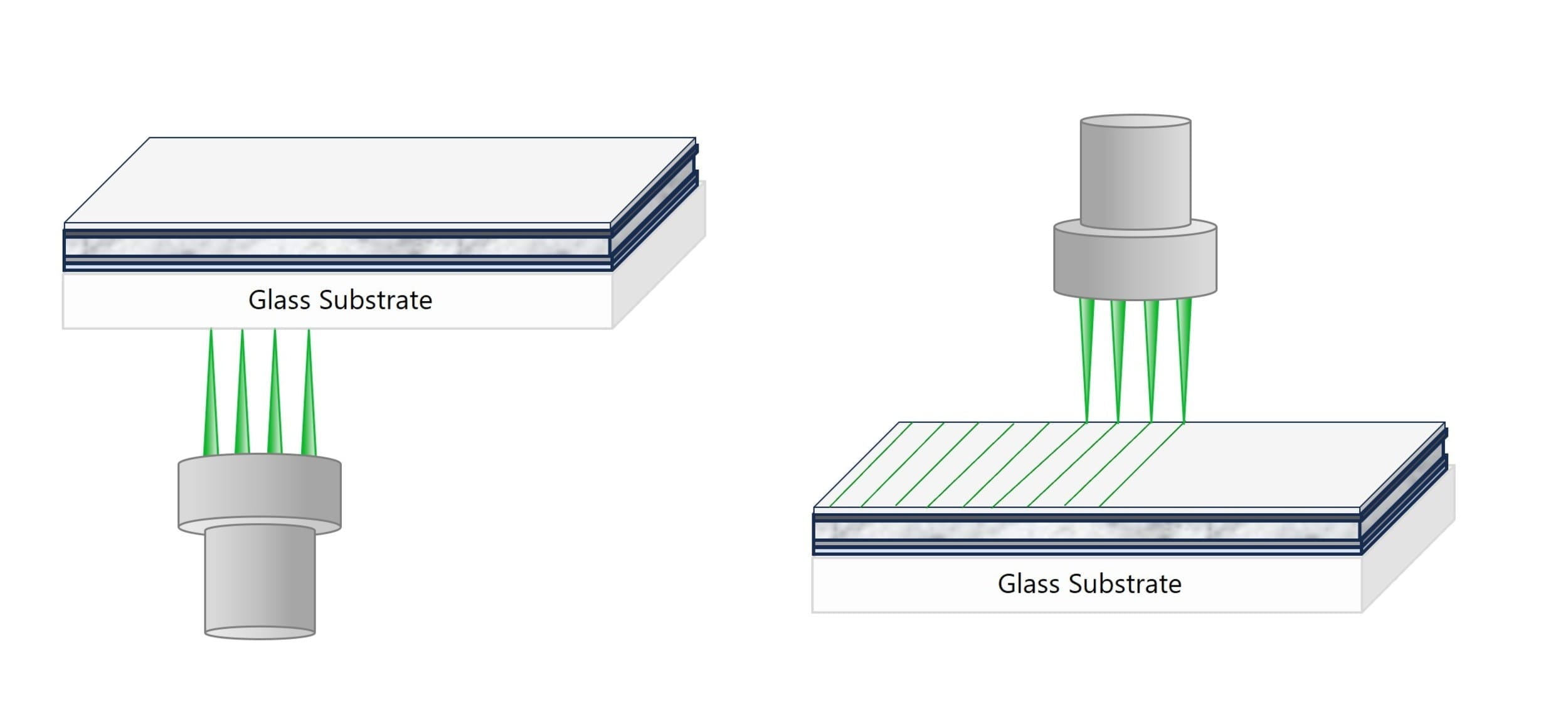

Whether MBSS workable for laser beam flying system? Which laser scribing technology is suitable for MBSS, input from glass side or from the film side?

Due to the light weight, MBSS can be installed flexibly in the way of laser scribing from bottom to up for inputing via glass side, or laser scribing from up to down for inputing via the film side.

Laser input from glass side (left) and from film side from film side.

You have further questions? Contact our expert for optics and optical systems: