Complex and customized polymer optics to enable next-gen applications:

Expertly crafted high-precision polymer optical solutions, from individual components to fully assembled opto-electronics: all under one roof.

Pushing the boundaries of what is possible

Our comprehensive services ensure seamless integration, precision, and unparalleled quality, tailored to your unique requirements. We have been pioneers in the realm of polymer optical solutions, harnessing the precision of advanced injection molding techniques to craft complex optical components and sophisticated opto-electronics.

- 40 years of visionary expertise in the field of polymer optical solutions

- Tailored solutions and production lines

- From prototype to production scale

Collaborate with us from the start and we'll co-develop solutions that elevate your product to new heights.

At a glance: Our comprehensive suite of expert services

Jenoptik has comprehensive know-how and state-of-the-art facilities to deliver your solution from one source.

- Conceptual polymer optical design to robust optical coating

- Opto-electronic packaging to automatizaton

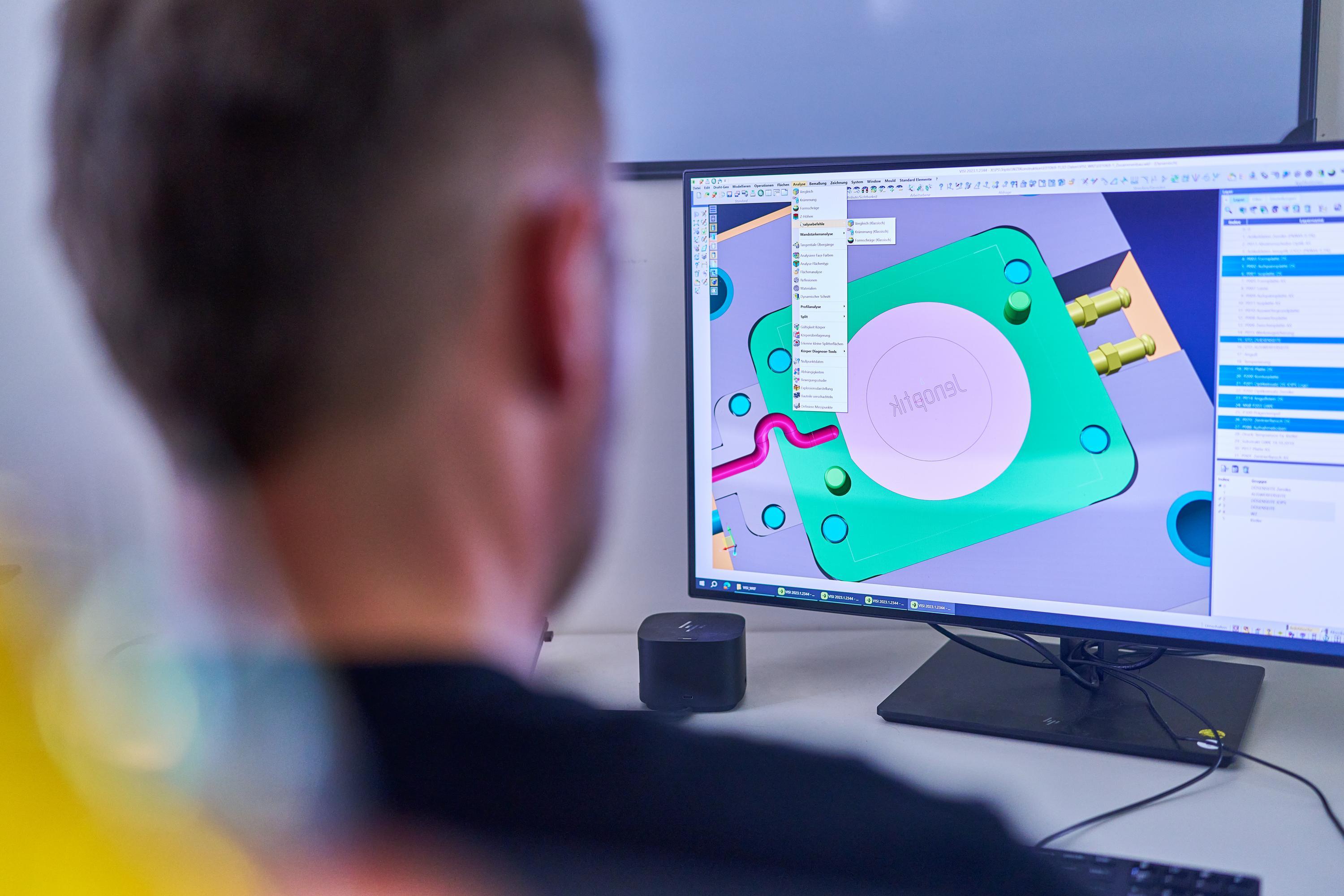

Collaborate with Jenoptik to develop and optimize your polymer optical solution in four seamless steps

Optical design & prototyping

Tooling & Optimization

Optical coating & Packaging

Industrialization & QM

Here are just a few highlights from our comprehensive range of services - where innovation meets precision.

Learn more about how polymer optics can drive innovation and growth in your industry

As the field of polymer optics continues to advance, it is poised to unlock a wide range of future solutions, from industrial applications to breakthroughs in medical imaging. Explore our cutting-edge polymer optical solutions and discover the expertise behind our innovative designs and precision polymer manufacturing. Dive into our showcase of successful projects and learn how our team of experts can bring your vision to life.Polymer Optical Solutions – enabling high‑precision and high‑volume production

The range of expertise we bring to high-precision polymer optics is truly exceptional. Beyond our R&D expertise, we also prioritize safe industrialization, keeping a close eye on regulatory compliance.

Below is just a glimpse of the services we offer to elevate your next solution. For the full portfolio, please get in touch with us!

Explore the possibilities: Our support for your next-gen device

- Versatile Technologies

- Complex Optics

- High‑Volume & Certified

- Broadband anti‑reflective (AR) layers

- Spectral filters

- Metallic mirrors

Fully automatic ultra precise alignment

- Industry-Leading Accuracy

- Unmatched precision: +/- 1 μm accuracy for precise measurements and data acquisition

- Automated calibration: Effortless adjustment and calibration for enhanced reliability and reduced downtime

- Versatile applications: Suitable for various industries

Ensuring ultra precise assembly

.jpg?impolicy=aoiv1&width=620&height=465)

Our ultra-precise assembly competency for polymer optical solutions and opto-electronics, sensor assembly and packaging is poised to revolutionize a wide range of applications, from consumer electronics to medical devices and aerospace technologies. By harnessing the power of precision assembly, we are empowering innovators and manufacturers to create polymer optical systems that are more efficient, more compact, and more powerful than ever before.

- Ultra fast UPT prototyping of polymer optics with tight tolerances

- Dicing up to 12 inch and several materials

- Die-Bonding in the area of thenths of milimeter

- Wire-Bonding up to 75 µm

- Housing and encapasulation

- Testing

Explore the possibilities: Our support for your next-gen device

Let's streamline the process and boost efficiency: by 2K injection molding

By utilizing 2-component injection molding, we merge two separate steps into one seamless process, increasing efficiency and reducing production time. This innovative approach for polymer optical solutions allows us to combine two different materials and/or colors into a single operation, resulting in a more streamlined and cost-effective manufacturing process - even for high volumes and medical components.

- Enabling less assembly steps

- No complex and costy assembly of components

- Shrinkage compensation

- High performance optical properties & surface accuracy

- Two different materials and/or colors

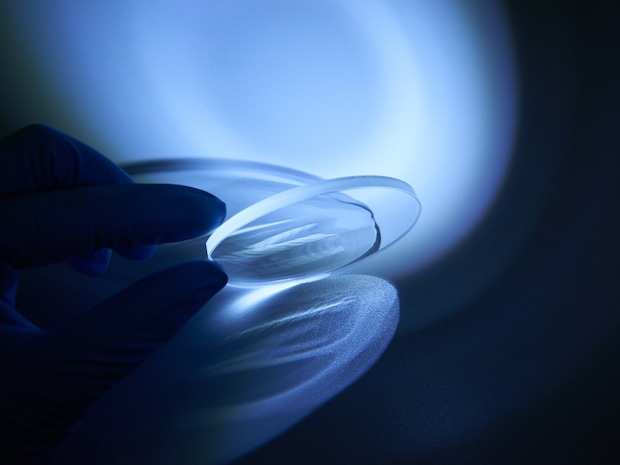

Best image quality with aspherical polymer lenses

Injection molding and stamping procedures are used to produce polymer optics with aspherical surfaces at the same cost as spherical optics.

Our aspherical polymer lenses have a non-spherical surface to improve the quality of optical images. Using a diamond processing method, we produce high-precision aspherical lenses and tool inserts very efficiently. We use these in turn to mold aspherical polymer lenses. Depending on the size and shape, these lenses can achieve a global dimensional accuracy of PV < 1µm and micro roughness of Ra < 10 nm.

With the injection molding and stamping procedure, aspherical polymer surfaces can be molded just as precisely as spherical surfaces — for the same cost. Therefore, aspherical contours are therefore widely used in polymer optics.

- Diameters from < 1 mm to 300 mm UPT-optical inserts

- PV depending on size and shape up to <1 μm

- Surface roughness optical inserts <10 nm

- Multi-cavity

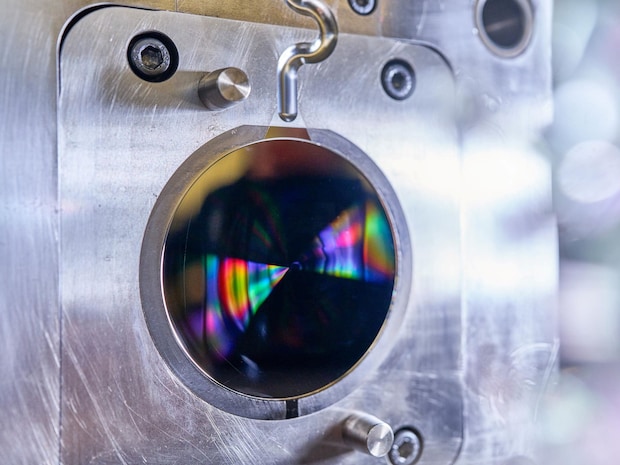

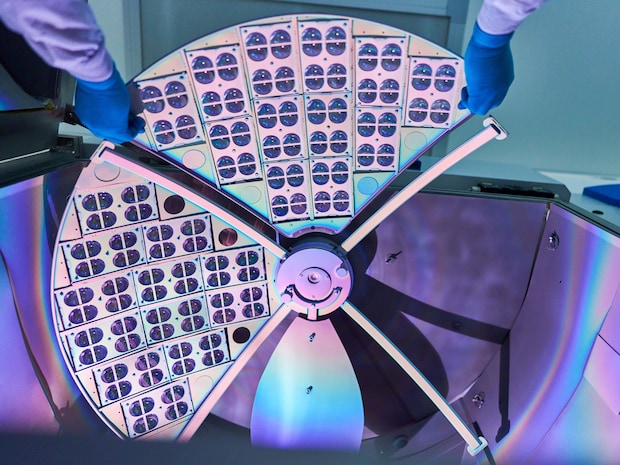

Coating Improves the Quality of Polymer Optics

Jenoptik offers a range of AR coatings that allow you to adapt light to meet your requirements.

Polymer optics are used in many different industries — in camera systems, head-up displays and reflectors for LED lighting. Polymer is ideal for these applications and can be manufactured in large quantities at a low cost. Coatings increase the quality of polymers significantly.

In this process, the optics are covered with a coating of thin metals and dielectrica. The coating is used for the reflection, antireflection, splitting or filtering of light beams. It can be used to suppress specific light components or prevent light reflections from occurring. All of our surfaces are protected against mechanical and chemical influences as well as scratches and dirt.

Optical coatings from Jenoptik offer impressive precision and reliability. Our experts regularly check our processes by means of measurements, analyses and climate testing. As we have many years of experience and a wealth of expertise, we can give you expert advice, when it comes to choosing the right coating for your requirements.

Compact and not rotationally symmetrical polymer free-form optics

Free-form optics are not rotationally symmetrical and can be used, amongst other things, for the collimation of light, beam formation, imaging and complex light diffusion. The optics have asymmetric characteristics. To ensure accurate processing of these polymer optical solutions with ultra-precise lathes, special experise is required along the entire process chain. At Jenoptik we take care of free-form optics projects from the design stage through to system integration.

With our Slow Tool Servo technology, we can produce high-precision free-form optics with diameters ranging from 1 to 350 mm. We use a modified diamond turning procedure, which uses a controlled rotation axis as well as two linear axes. The part of the free-form optics that is not rotationally symmetrical is achieved by means of a dynamic movement of the tool toward the optical axis.

The process is ideal for diamond processing of polymers (PMMA, Zeonex, PC, PS) and metals (nickel-phosphor, aluminum, copper, brass). Depending on your particular application, we can produce the free-form optics in a wide range of shapes.

- Sophisticated tooling expertise of complex freeform optics

- High precision molding & CCM quality control

- Functional injection molding

Highly efficient production of polymer optical solutions: precision polymer lenses, tailored to your vision

.jpg?impolicy=aoiv1&width=620&height=465)

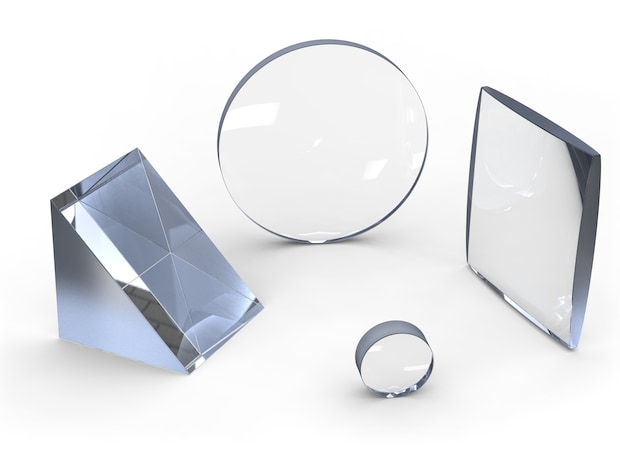

A lens is an optically effective component with two refractive surfaces. At least one surface of the lens is not a plane face. This increases the quality of images. Jenoptik offers lenses in a wide range of shapes for your specific polymer based applications: From the prototype to large-scale production, we can produce

- Aspherical lenses

- Cylinder lenses

- Lens arrays

- Lenses with free-form optics

- Toric lenses

We offer expertise along the entire technology chain — from component design, tool construction, injection molding and optical coatings through to fully automatic production. Our production is technologically adapted to your specific batch size and is designed to deliver a very high degree of dimensional accuracy.

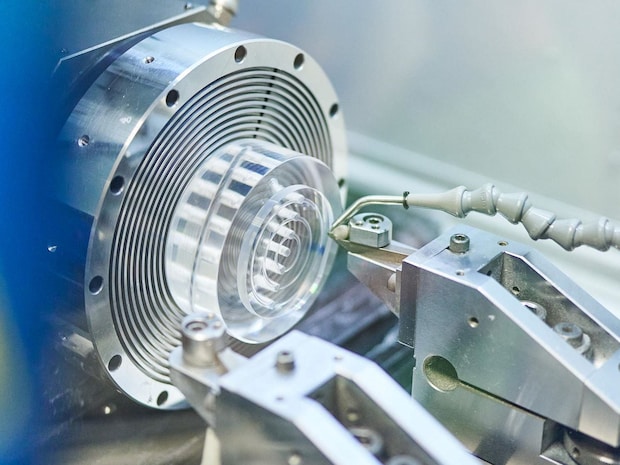

Spherical and aspherical polymer fresnel lenses as individual items or in small batches using ultra-precision lathes

Polymer fresnel lenses are divided into a set of concentric annular sections. The individual sections are then merged on a plane. These lenses are ideal for optical applications in the fields of lighting, medical, science, machine vision, photography and photovoltaics, for example.

Thanks to ultra-precise processing technologies such as diamond tools and lathes, we can realize fresnel structures with very small groove distances as small as 0.05 mm. On our special lathes, we produce precise spherical and aspherical fresnel lenses as individual items or in small batches. Convex, concave or even bi-focal structures can be produced, adapted perfectly to your specific requirements.

- Customized designs possible due to inhouse tool and UPT shop

- Individual designs with sharp inner and outer edges & high form accuracy

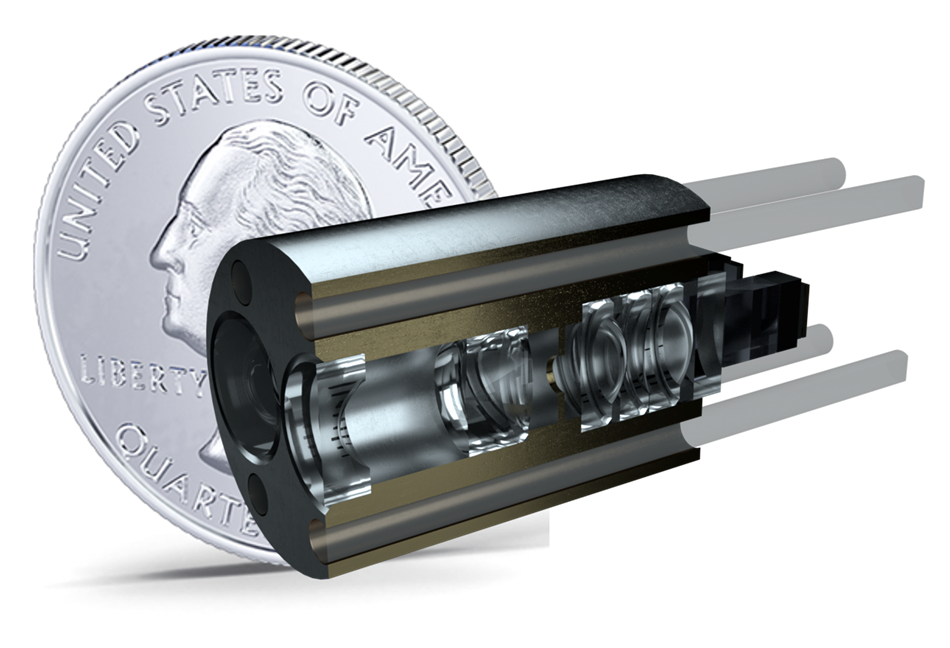

Polymer Microoptics: Miniature Polymer Optical Components

The diffractive components and micro lens arrays from Jenoptik represent the state-of-the-art in microoptics.

Components and assemblies are becoming ever smaller and more compact. That is why Jenoptik strives to constantly refine its optical elements and technologies. Our microoptics help you to meet the strict size and weight requirements in your industry and optimize your products.

Polymers open up a host of new opportunities in microoptics. Polymers are the main components in the production of new, lightweight elements. Using our state-of-the-art injection molding technology and the appropriate finishing process, we create micro-components that can be adapted to your exact needs. The special micro injection molding machines at Jenoptik offer maximum precision and make all microoptical components according to your requirements.

Polymer Objective Lenses: Light, Cost-Effective and Versatile

Lightweight polymer objective lenses from Jenoptik can be used cost-effectively for applications in a wide range of industries and markets.

We adapt the shapes and coatings of our polymer objective lenses to your requirements, allowing you to integrate the modules in the smallest of spaces with extreme precision.

Polymer aspheres simplify your lens systems, for example, so you can reduce weight and save money. We can also produce hybrid designs for you. For example, you can optimize image quality by using polymer objective lenses with high-index lenses.

The freedom of design granted during the design stage allows for cost-effective use of these optical components in industries such as the automotive industry, the medical industry and in the field of optical metrology. Contact us for advice on which polymer objective lenses are suitable for your particular applications.

Polymer optical solutions with prismatic surfaces for a wide range of applications

Polymer prismatic surfaces can be used to deflect light beams and achieve spectral splitting. Polymer optics offer the advantage of enabling you to integrate prismatic surfaces together with other optical functional surfaces and mechanical functional elements in one component. For example, you can use spherical and aspherical lenses, cylinder lenses or micro structures together with prisms. The components are produced in just one work step using sophisticated injection molding and stamping processes, saving you both time and cost.

Jenoptik produces prismatic surfaces of 0.01 - 100 mm for your specific applications.

- Prism sizes range from tiny components to greater assemblies

- Customized shapes & designs

- High angle accuracy

- CCM measurements for quality assurance

Metal mirror coating reflect light consistently and effectively - even for polymer optical solutions

Silver mirrors offer excellent VIS reflection properties and are used in moderate environmental conditions. Gold mirrors have a proven track record in the infrared spectral range in particular. The reflection properties in this range are excellent and offer long-term stability.

If metallic solutions are not suitable for your optical application, we can also offer dielectric mirrors on polymers for certain wavelength ranges. Therefore, we have developed procedures for a range of transparent and non-transparent polymers. We can also apply mirror coatings to substrates with complex three-dimensional shapes.