RecommendMail Facebook LinkedIn

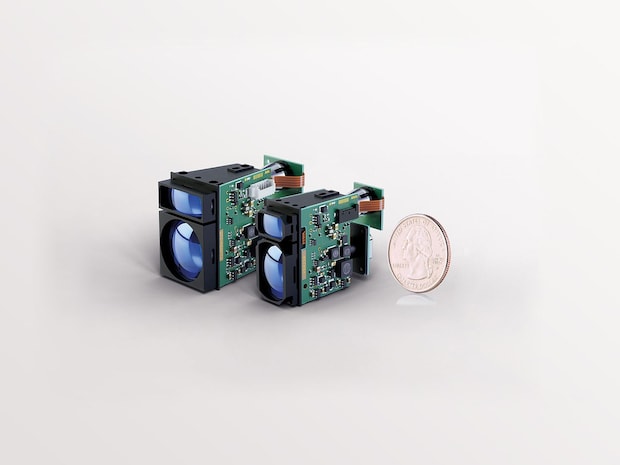

Laser rangefinder for precise measurement and monitoring

With Jenoptik's laser rangefinder, you can measure distances and positions in the range of a few centimetres up to 60 kilometres - contact-free, fast and with millimetre precision.

Our laser rangefinder measure the distance to objects precisely and quickly - even under the most difficult visual conditions.

Jenoptik's laser rangefinder provide fast and precise measurement data with a long range - even under difficult conditions. Even in poor visibility and extreme temperatures, they measure distances to detected targets accurately and reliably. This allows users to assess the situation immediately and respond to threats.

Our laser rangefinders cover a wide range of distances and applications.

Laser rangefinder at a glance

Exactly: LDM Series

- Range up to 3 km

- Measuring frequency up to 40 kHz

- Measure to the millimetre

Fast: DLEM Series

- Range up to 20 km

- Low weight

- For ambient temperatures between -40 °C and +80 °C

Far: ELEM Series

- Range up to 60 km

- Measuring frequency up to 15 Hz

- Measuring accuracy up to 3 m

In single pulse laser distance measurement (ELEM), a laser rangefinder emits a short laser pulse whose start time is recorded. The laser pulse travels to the desired target and back to the starting point. The total travel time of the laser is measured with picosecond accuracy by the laser rangefinder. The distance is then calculated based on the known speed of light.

In contrast, diode laser rangefinders (DLEM) send several thousand laser pulses. The echoes of all the individual laser pulses are superimposed and sophisticated software algorithms process the collected echoes. This allows the distance of hard targets to be measured, while soft targets are disregarded.

The diode laser rangefinder are commonly used in handheld surveillance systems, highly mobile fire control systems, high performance gimbal systems for UAVs and helicopters, and long range surveillance systems for border patrol.

The single-pulse laser rangefinder are most commonly used in sensor pods for aircraft, long-range observation and border control systems, and remotely controlled defence systems.

+81 045 670-9141