Opticline SPC Measuring Stations from Jenoptik for Your Optical Shaft Measuring Technology

Our Opticline SPC measuring stations are ideal for quality control, and make the optical, non-contact measurement of shaft-shaped workpieces much easier.

Opticline SPC measuring station

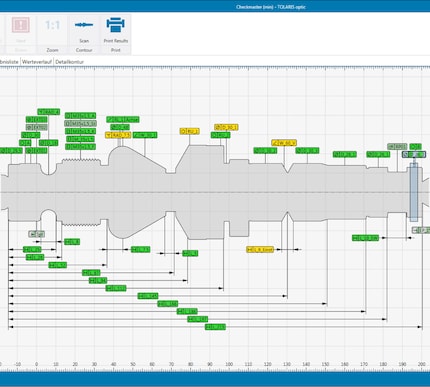

The SPC measuring stations are fitted with various interfaces for statistical process control (SPC). These allow extremely efficient monitoring of the manufacturing process, and allow rapid intervention where necessary. This ensures that you can produce workpieces of a consistently high quality. The measuring systems are simple to operate, allow non operator-dependent measurement results, and deliver easy to understand measurement results with analysis functions where required.

The new Opticline C-Series generation

The New Opticline. Measure Your Benefits.

Success requires innovation, experience and quality

Our Opticline systems offer a number of intelligent self-monitoring functions for lasting quality assurance. Moreover the systems set new standards in terms of traceability and the documentation of your quality parameters

This guarantees the maximum level of quality for your production process, ensuring your company can achieve long-term economic success.

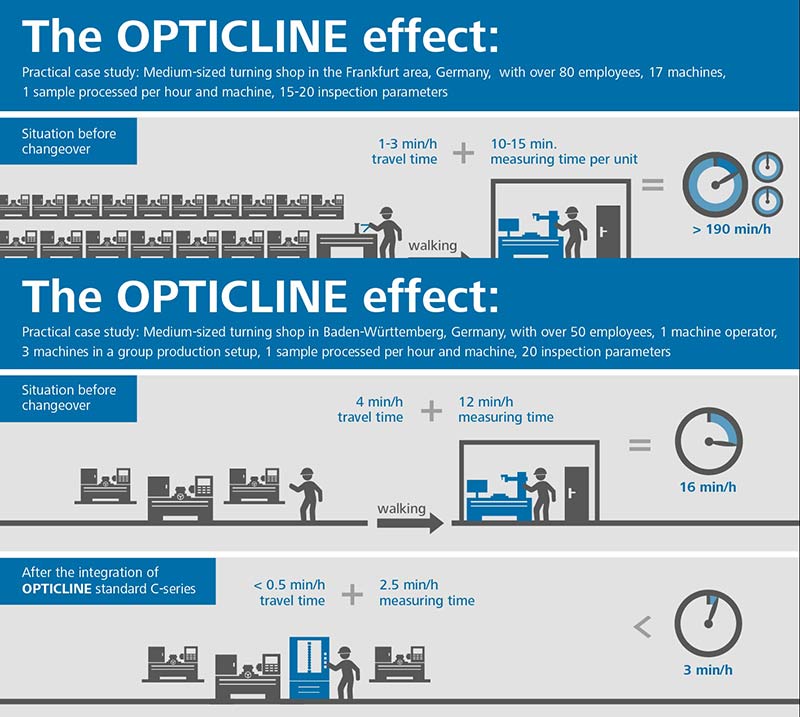

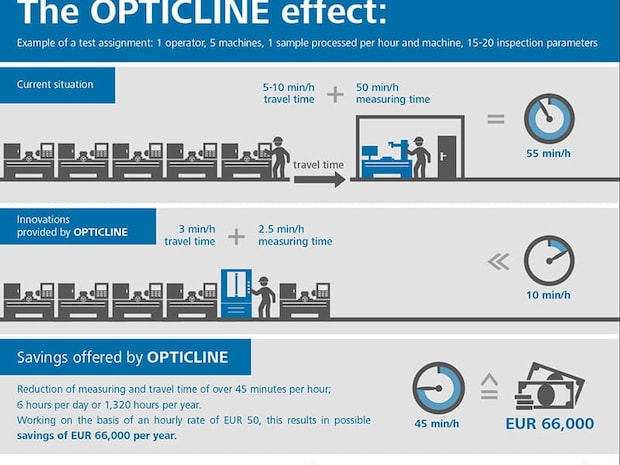

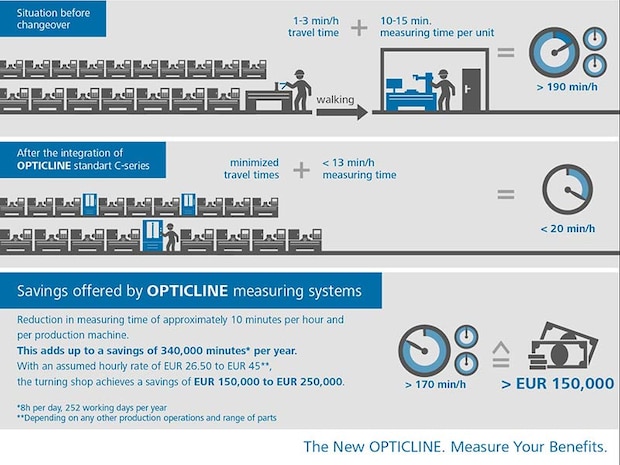

Measurably Closer to Production

Opticline effect measurably closer

Cut routes, bring outlay down to a minimum, save on rework and reduce the sources of error. Put your trust in maximum ease of operation and the longest possible service life. For maximum reliability in production.

Measurably Faster Processes

In doing so, they take speed to a whole new level of quality and offer a whole new approach to complex applications. Whether it is creating test plans or performing complicated measurement runs, our evaluation software provides you with reliable support for whatever task you need to complete. For quality assurance with the maximum level of reproducibility and precision.

We offer various models within the Opticline C-series. These differ from each other in terms of their workpiece capacity. You choose the measuring system that precisely meets your requirements. Smaller and larger workpieces of up to 900mm in length can be measured to the micrometer.

System Highlights

- Top resolution and measurement accuracy across the entire range thanks to a unique, cascaded camera system for workpieces with diameters of up to 320 mm.

- Adaptation to your integration requirements – horizontal or vertical design.

- Split-second measurements, even with very large workpieces.

- Available for operator self-inspection and fully-automated use.

Measuring capacities of the C-Series

- Lengths up to 200/300/600/900 mm

- Diameters 50/100/140 mm

- Part weights up to 20kg

Measuring capacities of the C10xx series

- Lengths up to 1000 mm

- Diameters up to 140/230 mm

- Part weights up to 40 kg

C10xx for specific requirements

- Optional probe for tactile measurements of concentric axial runs and lengths that can be seamlessly integrated into the optical measuring sequence

- Measuring system C1023-75AE with specially optimized camera system, high-precision C-axis and highest-resolution angle measuring system for measuring crankshafts up to 75 kg

Scope of delivery

- Measuring machine

- Measuring and evaluation computer

- Measuring and evaluation software for Windows

- Standard clamping devices and accessories

- Machine documentation

- Operating instructions and software documentation

Download

Benefits

- Precise and versatile: Complete, high-resolution, and precise measurement of various measurement tasks in seconds with no operator influence on the measurement results.

- Efficient: Carry out operator checks at the machine,monitor workpieces during manufacture, and respond quickly.

- Convenient: Intuitive test plan creation and operation, clear and transparent results display, minimal training required.

- Flexible: Suitable for a wide range of workpieces, minimal setup times, and effective in flexible production.

- Reliable and suitable for manufacturing: Intelligent and automated monitoring of the measuring system, robust construction, temperature compensation, no setting master required for daily use.

Applications

- Automotive industry: Measurement of turbochargers, engine valves, pistons, camshafts and crank shafts, gear shafts and drive shafts.

- Turned and ground parts producers: Measure shaft-shaped, largely axially symmetrical workpieces.

- Medical technology: Measure implants, bone screws, and rotating instruments.

Product Views

Product recommendations

+49 7721 6813-288